When it comes to choosing the right material for industrial, commercial, or manufacturing applications, understanding the differences between various types of polyethylene is crucial. Polyethylene is one of the most widely used plastics in the world, and its different variations—LDPE, LLDPE, and HDPE—each offer unique properties that make them suited to specific uses. This article delves into the differences between LDPE, LLDPE, and HDPE sheets, focusing primarily on HDPE sheets and their exceptional performance in various industries. By understanding the characteristics, benefits, and uses of each type of polyethylene, you can make a more informed decision for your material needs.

1. LDPE (Low-Density Polyethylene)

LDPE, or Low-Density Polyethylene, is one of the oldest and most widely used forms of polyethylene. Known for its flexibility and ease of processing, LDPE has been utilized in many everyday products. LDPE sheets are known for being flexible but have lower strength compared to other polyethylene types. This makes them ideal for applications where flexibility and low-density properties are more important than strength.

Characteristics:

Flexible and soft.

Lower strength and rigidity.

Resistant to moisture and chemicals but not as durable as other polyethylene types.

Common Uses:

Plastic bags and films.

Food packaging.

Protective covers and liners.

Toys and household products.

While LDPE’s flexibility and lower density make it a popular choice for certain applications, it is not suitable for situations that demand high strength or impact resistance.

2. LLDPE (Linear Low-Density Polyethylene)

LLDPE, or Linear Low-Density Polyethylene, is a variation of LDPE that is produced using a different polymerization process. This results in a material with similar characteristics to LDPE but enhanced strength and flexibility. LLDPE sheets are stronger and more durable, offering better impact resistance and tensile strength than their LDPE counterparts.

Characteristics:

More flexible and stronger than LDPE.

Good chemical resistance and higher durability.

Better stress-crack resistance.

Common Uses:

Stretch films and wraps.

Agricultural films.

Container linings and packaging.

Automotive parts.

LLDPE’s enhanced properties make it ideal for applications where additional strength and durability are required, but where flexibility and low-density properties are still desirable.

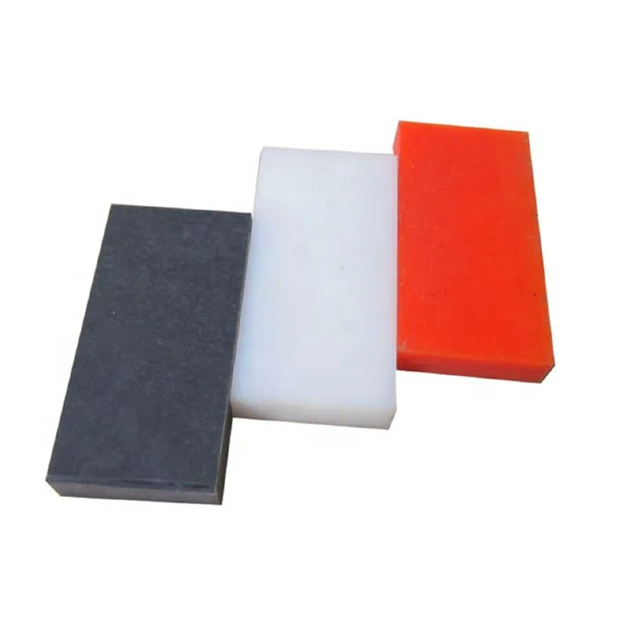

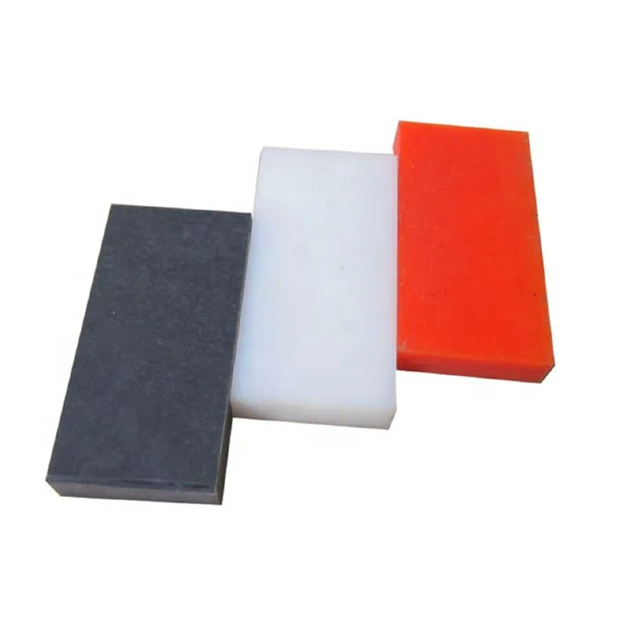

3. HDPE (High-Density Polyethylene) Sheets

HDPE, or High-Density Polyethylene, is a more rigid and stronger form of polyethylene. It is produced using a different polymerization process that creates tightly packed molecules, resulting in a material that has a higher density compared to LDPE and LLDPE. HDPE sheets are known for their outstanding strength, durability, and resistance to environmental factors, making them perfect for harsh environments and demanding applications.

Characteristics:

High strength, stiffness, and impact resistance.

Excellent resistance to chemicals and abrasion.

Highly durable, with low moisture absorption.

Suitable for both outdoor and industrial applications.

Common Uses:

Construction of tanks, liners, and protective barriers.

Industrial applications where high strength is required.

Food processing and pharmaceutical industries, due to FDA-approved materials.

Containers and pipes for fluid and gas transportation.

One of the standout features of HDPE sheets is their ability to withstand extreme temperatures and chemicals, making them suitable for a wide range of applications, from construction to food industries.

4. Comparison of Properties

When comparing LDPE, LLDPE, and HDPE sheets, it’s important to consider several key properties: strength, flexibility, impact resistance, and chemical resistance. Each polyethylene type excels in different areas, depending on the needs of the application.

Pros and Cons:

LDPE: Best for applications requiring flexibility and low-cost manufacturing, but unsuitable for environments requiring high strength or impact resistance.

LLDPE: A good middle ground between LDPE and HDPE, offering better strength and flexibility. It is commonly used in applications such as stretch films and container linings.

HDPE: The strongest and most durable of the three. It is perfect for demanding industrial and commercial applications that require high strength, impact resistance, and chemical resistance.

5. Which Polyethylene Should You Choose for Your Application?

Choosing the right polyethylene material depends on the specific needs of your application. Here’s a quick guide to help you decide:

Use HDPE sheets when you need high strength, durability, and resistance to chemicals, abrasion, and impact. HDPE is ideal for industrial applications such as tank construction, food processing, and the creation of protective barriers. If your application involves harsh environments or heavy-duty performance, HDPE is your go-to material.

Use LLDPE sheets when you need a balance between flexibility and strength. LLDPE is ideal for stretch films, agricultural films, and other packaging materials that require both flexibility and durability. It’s perfect for applications where some strength is needed but flexibility cannot be sacrificed.

Use LDPE sheets if you need a material that offers high flexibility but isn’t required to endure high stress. LDPE is great for lightweight packaging, bags, and other products where low cost and ease of processing are more important than strength.

Conclusion

Choosing the right polyethylene material for your needs can significantly impact the efficiency, cost-effectiveness, and performance of your product. HDPE sheets are an excellent choice for heavy-duty applications that demand high strength, durability, and resistance to various environmental factors. Whether you are constructing tanks, liners, or barriers, HDPE offers reliable performance that can withstand harsh conditions and reduce maintenance costs.

At Tianjin Beyond Technology Developing Co., Ltd, we specialize in the production of high-quality engineering plastics, including HDPE sheets, that cater to a wide range of industrial applications. With over 10 years of experience in the industry, our company is committed to delivering durable and cost-effective solutions tailored to meet your specific requirements.

Contact Us

If you’re interested in learning more about our HDPE sheets or need assistance selecting the right material for your project, feel free to get in touch. Our team at Tianjin Beyond Technology Developing Co., Ltd is here to provide expert guidance and high-quality products to help you achieve the best results.

For inquiries, please contact us at [your contact information]. Let us help you make the right material choice for your business!