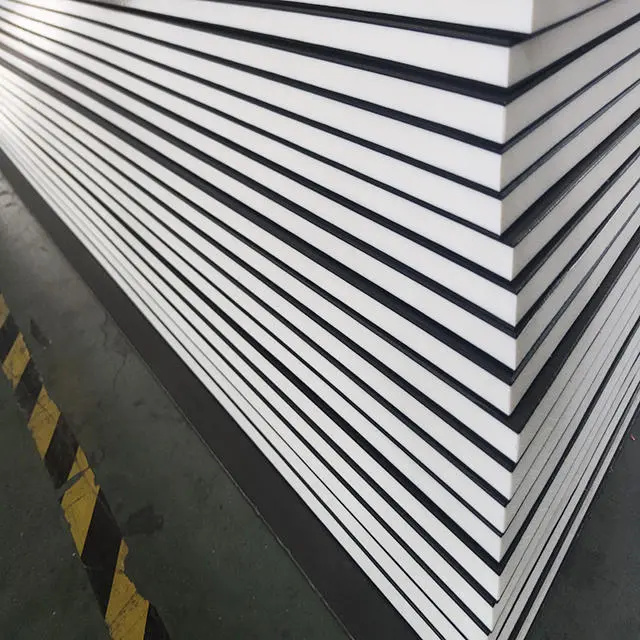

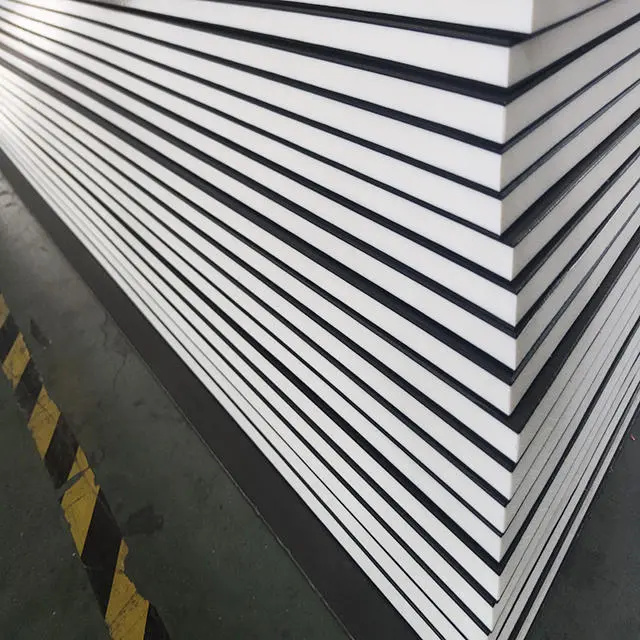

For many applications across various industries, HDPE is chosen as one of the best materials because of its versatility, toughness, and cost-effectiveness. Chemical storage tanks, packaging material, or even outdoor furniture, all can be made out of High-Density Polyethylene sheets because they are so strong and can resist many challenging environments.

HDPE is high-density polyethylene. It is produced through the polymerization of ethylene and is derived from petroleum. Its unique properties have made it an extremely valuable material in all sectors, particularly for commercial and industrial uses. Due to its high-density molecular structure, HDPE acquires excellent strength along with resistance to impacts and chemicals. Thus, heavy industrial applications can find a competent replacement as the earth-friendly manufacturer sustains it. Herein we shall discuss in more detail the properties, applications, and benefits of HDPE sheets concerning their indispensable nature in today's world.

Key Characteristics of HDPE Sheets

Durability and strength are the main characteristics of HDPE sheets. The material is known for durability and strength, for most applications. Therefore, these are some of the key features of HDPE sheets:

Durability and Strength

HDPE has very good mechanical properties and can resist physical stress excellently. Due to its high-density configuration, it is strong in tension. Therefore, HDPE sheets are capable of carrying heavy loads and serving in very harsh weather conditions where there is a need for high performance, such as tank liners, structural support, and barrier protection.

One of the most important features of HDPE is its excellent resistance to chemicals. It resists most chemicals, including acids, bases, solvents, and oils. Therefore, HDPE sheets are primarily fit for the chemical processing industry, waste management industry, or environmental engineering industry concerning direct contact with harsh substances. Chemical robustness means that HDPE will not decompose, corrode, or react with the materials it comes into contact with; therefore, it is long-lasting in difficult industrial applications.

Moisture Repellent

Another key characteristic of HDPE sheets is the very good resistance to moisture they possess. Unlike many other materials, HDPE does not absorb water, and this makes it very appropriate for use in applications that are exposed to moisture or are usually wet. This includes agricultural equipment, water tanks, and plumbing systems where there is a constant presence of water or some other kind of liquid. HDPE's ability to resist water also means that it can withstand wet conditions without getting structurally compromised or even weaker over time.

HDPE sheets are UV resistant. Ultraviolet (UV) resistance is the single most important factor when considering outdoor use. A material that does not contain this important property can lose its strength and discolor after being exposed to the sun for a very short time. HDPE, however, does not lose any of its strength or color and can therefore be used in direct sunlight applications. This is why it is often a preferred material for outdoor furniture, playground equipment, and other outdoor installations where prolonged exposure to the sun is inevitable.

Strong Yet Lightweight

While maintaining its strength, HDPE is relatively light in weight compared to other materials of similar properties. This makes HDPE sheets easier to work with in handling, cutting, and installing, which ultimately saves on transportation and labor costs. The material is strong and durable for heavy-duty industrial applications as well as for lightweight everyday consumer products.

These outstanding qualities are responsible for the popularity of HDPE in so many different industries where it offers both functionality and long life in even the most rugged applications. Whether for structural or consumer applications, HDPE sheets deliver the perfect combination of strength, resistance, and usability, meeting the diverse needs of various industries.

Applications of HDPE Sheets

The use of HDPE sheets in many industrial applications is a result of their rugged durability and flexibility. Some customary uses include the following:

Industrial Applications

In an industrial environment, HDPE sheets prove their worth by surviving under drastic conditions. The chemical and impact resistance of HDPE sheets find them being used in tank, hopper, and silo linings. As a protective barrier material, HDPE has other common uses in construction, providing both waterproofing and structural integrity. It is the pressure that the mining, material-handling, and chemical-processing industries put on their surroundings that places such reliance on HDPE sheets for their ability to take punishment and keep going.

Food and Beverage Industry

HDPE sheets are safe to use for food processing and packaging since they meet the strict safety requirements. They are FDA-accredited to accustom food directly over them, thus making them applicable for usage in all food-related applications, while producing foodboards, storage boxes for foodstuffs and even used on working countertops within the processing department. Due to its bacterial and moisture resistance, HDPE proves to be a hygienic material that promotes safety and cleanliness within areas that either make, pack, or keep foodstuffs.

Packaging

HDPE is so strong and moisture resistant that it found its application in the packaging industries. It is a material used to produce bottles, containers, and crates among many other packaging solutions. Chemicals, moisture, and UV rays do not affect it; thus, it is suitable for consumer goods and industrial packaging where durability and long life are important.

Medicines and Pharmaceuticals

Used for applications in the medical and pharmaceutical fields, HDPE sheets are appreciated due to their chemical inertness, ability to withstand sterilization processes, and non-reactivity. They find use in the manufacture of medical devices, containers, and storage tanks where keeping products safe from contamination is necessary. The simplicity of HDPE in cleaning also allows its utilization in applications that require a clean environment, for instance pharmaceutical production and hospital sectors.

Consumer Products

Apart from industrial and professional uses, HDPE sheets are applied in the manufacturing of diverse consumer products. Because it is lightweight and easy to work with, the product proves to be long-lasting and easy to handle, such as outdoor furniture, playground equipment, and storage solutions. This material can withstand different weather conditions and UV rays; therefore, it assures that these consumer products last longer and remain attractive even after being battered by the elements.

The diversity of applications of HDPE sheets speaks to the extent of their use in different sectors of the economy for industrial applications that require high durability and resistance to chemicals or for consumer products that need to be UV resistant and strong. In either regard, HDPE sheets are used to provide an effective solution in many sectors based on their stability and ability to perform under difficult conditions, which in turn makes them invaluable in contemporary manufacturing and designing.

Benefits of Using HDPE Sheets

Their popularity among various industries is based on the many benefits of HDPE sheets. Here are some of the most important advantages of HDPE sheets:

Eco-Friendly and Recyclable

One of the most compelling reasons to choose HDPE is for its environmentally friendly aspect. HDPE can be recycled 100%, thus reducing waste and adding to sustainability practices in industries across the globe. Being very durable, HDPE offers a long service life and does not require frequent replacement, thus minimizing the impact on nature. In addition, HDPE is non-toxic and does not involve compounds harmful to health, such as BPA. Thus, it is safe for applications to both consumers and industry. This makes it a perfect choice for companies willing to reduce their carbon footprint and comply with more and more environmental regulations.

Cost-Effective

HDPE sheets are an economical choice, especially considering their durability and no fret maintenance features. Being wear and tear, chemical, and weather resistant, the material does not need to be replaced now and then which cuts long-term costs. Besides, its quality of being lightweight reduces the expenditure on transportation and handling as contrasted with heavier metals or other alternative plastics. Therefore, HDPE proves to be an economically feasible option over a wide range of applications, specifically in sectors where financial resources are the foremost concern.

Ease of Fabrication

HDPE sheets provide another considerable advantage through their ease of fabrication. They cut, weld, thermoform, and machine well. They can be transformed in every way imaginable to fit the needs of manufacturers in terms of offering specific solutions regarding industrial and consumer products. HDPE takes engraving, printing, and coloring well, hence further modifications to fit branding or even functional specs.

Low Maintenance Usage and Longevity

Being a plastic material, HDPE sheets require very little maintenance and thus can be used as a low-maintenance material in various applications. The material does not corrode or degrade with time, making it long-lasting. It can bear chemical exposure, moisture exposure, and UV exposure without showing any signs of wear. Such high durability combined with resistance toward environmental conditions indicates that the HDPE product will bear a long life much beyond maintaining or replacing some other material, thus saving time and money.

Harsh Environment Product Performance

HDPE performs excellently under harsh conditions, which makes it suited to industrial and outdoor uses. It can maintain strength and shape in those extremes of temperature, moisture, or even contact with chemicals and UV light. Whether it's being used in chemical processing plants or outdoor furniture that gets sun and rain or water tanks for agriculture, HDPE will give reliable service where other materials would deteriorate from those environments.

These advantages have made HDPE sheets very popular among manufacturers and almost every industry in the world. They are environmentally friendly and cost-effective; in addition to being long-lasting, they are also user-friendly. So, these sheets provide that kind of solution which is a balanced mix between performance and sustainability, meeting different kinds of demands from varied sectors. Whether it is materials needed for industrial usage or consumer goods or products related to environmentally friendly production, HDPE offers many advantages.

Conclusion

In summary, HDPE sheets are highly versatile and long-lasting materials used in many fields. For industrial usage that requires strength and chemical resistance, to products for consumers designed for the outside area, high-density polyethylene provides unique durability, sustainability, and cost-effectiveness. Moisture, chemical UV resistance, and physical stresses make this material important in challenging applications. Recycling and being eco-friendly will also attract people who want them to reduce the impact they have on the environment.

With sustainability ever more at the top of the industrial agenda, the use of HDPE sheets will most likely be extended to an even greater extent than ever before. Whether it is for packaging, building, medical purposes or consumer goods, the long lifecycle of HDPE and good performance promises to keep it a material of choice for many years ahead. By using HDPE, producers receive far more than just its excellent qualities; they also work towards a future that is more environmentally responsible and sustainable.