UHMWPE (Ultra-High Molecular Weight Polyethylene) is a type of polyethylene with extremely long chains, resulting in a very high molecular weight. This unique structure gives UHMWPE its distinctive properties, including high impact strength, low friction, and excellent chemical resistance.

UHMWPE is known for its exceptional wear resistance, low friction coefficient, and high impact strength. These properties make it ideal for applications where durability and longevity are crucial. It is commonly used in industries such as mining, construction, and material handling.

Market overview

The global UHMWPE sheet market is experiencing substantial growth, driven by its diverse industrial applications. The market size is expected to reach USD 1.4 billion by 2030, with a compound annual growth rate (CAGR) of 7.8% from 2023 to 2030. The Asia-Pacific region, particularly China, is a significant contributor to the market’s growth, with a market size of USD 1.2 billion in 2022.

How to select the right UHMWPE sheet

Thickness

The thickness of UHMWPE sheets can vary significantly based on the intended application. Thicker sheets are generally more durable and resistant to wear and tear, making them suitable for high-impact applications. Thinner sheets, on the other hand, may be preferred for applications requiring flexibility and ease of installation.

Density

UHMWPE sheets come in various densities, typically ranging from 0.93 to 0.98 g/cm³. Higher density sheets offer greater resistance to abrasion and impact, making them ideal for heavy-duty applications. Lower density sheets, while still durable, may be more suitable for lighter applications where flexibility is a key requirement.

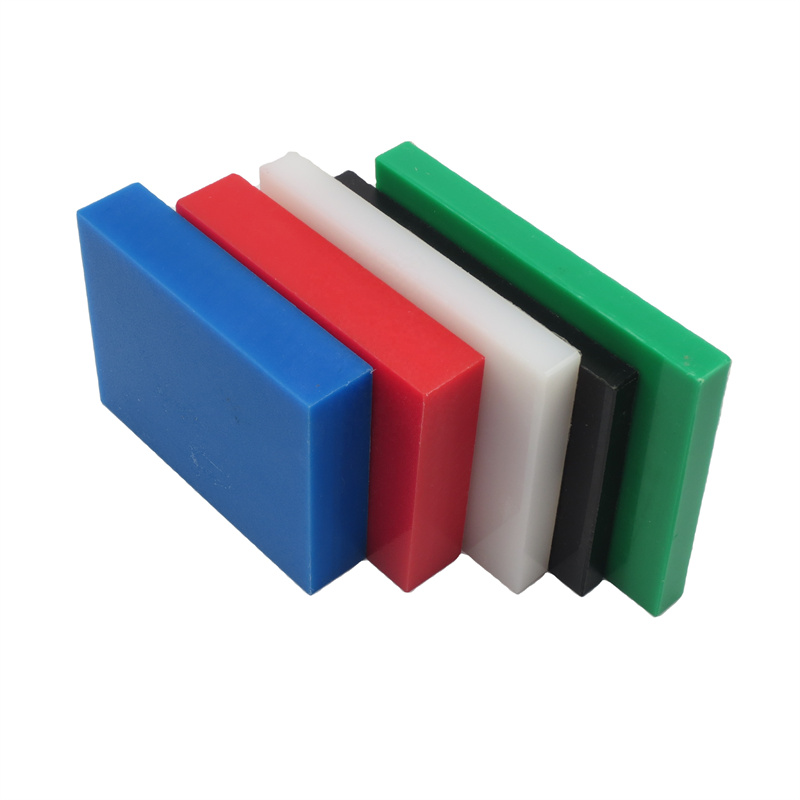

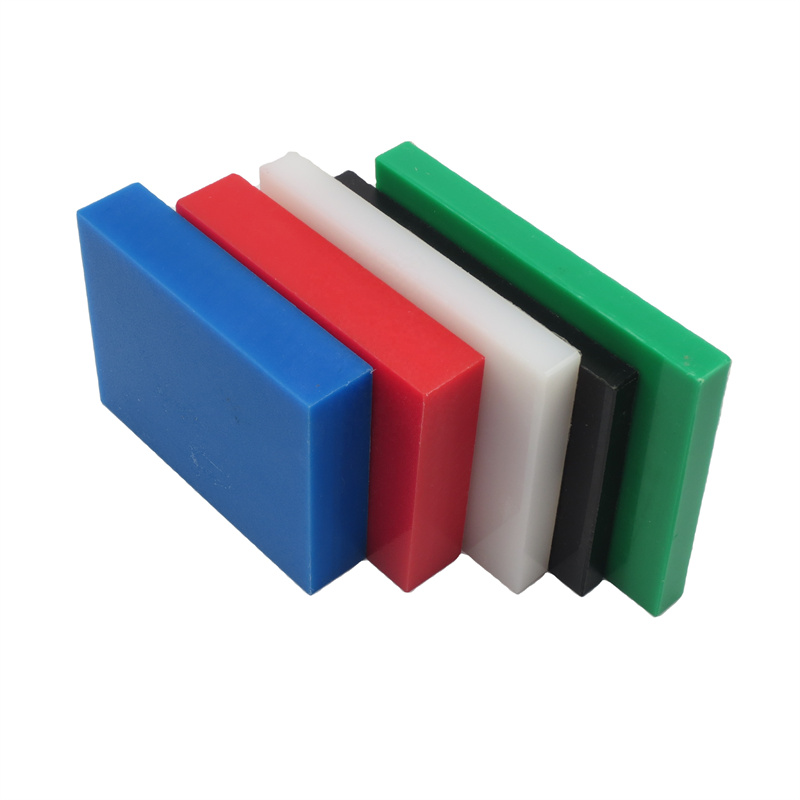

Color

UHMWPE sheets are available in various colors, which can be beneficial for identification and safety purposes. For instance, bright colors like yellow or orange are often used in industrial settings to enhance visibility and reduce the risk of accidents. Additionally, color-coded sheets can help differentiate between different grades or types of UHMWPE for specific applications.

Surface finish

The surface finish of UHMWPE sheets can significantly impact their performance in certain applications. Smooth surfaces are ideal for applications requiring low friction, such as conveyor belts or sliding components. Textured surfaces, on the other hand, provide better grip and are suitable for applications like flooring or walkways where slip resistance is essential.

Size

UHMWPE sheets are available in various sizes to accommodate different project requirements. Standard sheet sizes typically range from 48” x 96” to 60” x 120”, but custom sizes are also available. It’s essential to choose a sheet size that fits the specific dimensions of the application to minimize waste and reduce installation costs.

Temperature resistance

UHMWPE exhibits excellent temperature resistance, with a working temperature range of -40°F to 180°F. This makes it suitable for applications in extreme environments, such as cold storage facilities or high-temperature industrial processes. However, it’s important to note that prolonged exposure to temperatures above 180°F may cause the material to soften and lose its structural integrity.

Impact resistance

UHMWPE is renowned for its high impact resistance, making it ideal for applications involving heavy loads or dynamic forces. It can withstand repeated impact forces without cracking or deforming, ensuring long-lasting performance even in demanding conditions.

Chemical resistance

One of the standout features of UHMWPE is its exceptional chemical resistance. It is resistant to a wide range of chemicals, including acids, bases, and solvents. This property makes it suitable for applications in the chemical processing industry, as well as for manufacturing components that come into contact with aggressive substances.

UV stability

While UHMWPE is generally resistant to UV radiation, prolonged exposure to sunlight can cause the material to degrade over time. To ensure the longevity of UHMWPE products used outdoors, it is advisable to choose UV-stabilized grades or apply protective coatings to the surface.

Types of UHMWPE sheets

UHMWPE is available in various grades, each tailored to specific industrial needs. Some of the most common grades include:

Standard UHMWPE is the most widely used grade, known for its excellent wear resistance and low friction properties. It is suitable for a broad range of applications, including conveyor systems, chutes, and wear pads.

Medical-grade UHMWPE is specially formulated for use in medical applications, such as joint replacements and surgical instruments. It meets stringent biocompatibility standards and is resistant to sterilization processes.

Food-grade UHMWPE is designed for use in food processing and handling applications. It is compliant with food safety regulations and is resistant to chemicals commonly used in the food industry.

Wear-resistant UHMWPE is engineered for applications where high abrasion resistance is critical. It is commonly used in mining, construction, and material handling industries.

Anti-static UHMWPE is designed to dissipate static electricity, making it suitable for applications in electronics manufacturing and cleanroom environments.

Flame-retardant UHMWPE is engineered to resist ignition and slow down the spread of flames, making it suitable for applications in industries where fire safety is a concern.

UHMWPE sheets are available in various forms to suit different applications. Some common forms include:

UHMWPE rods are often used in applications where linear motion or rotation is required. They can be machined into custom shapes and sizes.

UHMWPE tubes are used in applications such as conveyor rollers, bearings, and bushings. They offer excellent wear resistance and low friction properties.

UHMWPE blocks are versatile and can be used in various applications, including wear pads, liners, and spacers.

UHMWPE films are thin and flexible, making them suitable for applications such as protective covers, packaging, and insulation.

When selecting UHMWPE sheets, it’s essential to consider the specific requirements of the application. Factors such as load-bearing capacity, environmental conditions, and compatibility with other materials should be taken into account to ensure optimal performance and longevity.

Conclusion

In conclusion, selecting the right UHMWPE sheet is crucial for ensuring optimal performance and longevity in various industrial applications. By considering factors such as thickness, density, color, surface finish, size, temperature and impact resistance, chemical resistance, UV stability, and the specific needs of the application, businesses can make informed decisions that align with their operational requirements and industry standards. Whether it’s for use in construction, manufacturing, or specialized industries, understanding the unique properties of UHMWPE and its various grades and forms is essential for maximizing efficiency, safety, and cost-effectiveness.