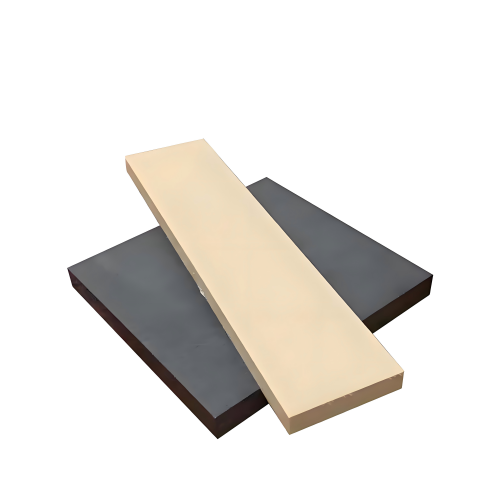

What is PVC Sheet?

PVC sheets, also known as expanded PVC or foam board, are lightweight, durable, and versatile materials widely used across various industries. Made from polyvinyl chloride, these sheets are easy to cut, shape, and paint, making them ideal for a range of applications.

Key Properties of PVC Sheets:

Lightweight: Easy to handle and transport.

Durable: Resistant to moisture, chemicals, and impact.

Thermo-formable: Can be heated and bent into desired shapes.

Paintable: Compatible with vinyl, acrylic, and polyurethane paints.

Common Applications:

Signage and Displays: Used for creating eye-catching signs and exhibition displays.

Costume Making: Popular for crafting lightweight armor and props.

Construction: Utilized in partitions, wall claddings, and insulation.

Photo Mounting: Provides a sturdy base for mounting photographs.

Why Cutting PVC Sheets is Essential

Cutting PVC sheets is a fundamental step in many projects. Whether you're creating custom signage, building displays, or crafting costumes, precise cuts ensure the final product looks professional and functions as intended.

Why It’s Needed:

Customization: PVC sheets often need to be cut to specific sizes or shapes.

Versatility: Different projects require different thicknesses and cuts.

Efficiency: Proper cutting techniques save time and reduce material waste.

Importance of Using the Right Tools and Techniques

Using the correct tools and methods for cutting PVC sheets is crucial. Improper techniques can lead to rough edges, material waste, or even safety hazards.

Why It Matters:

Precision: Ensures clean, accurate cuts for a professional finish.

Safety: Reduces the risk of injury from sharp tools or splinters.

Efficiency: Saves time and effort, especially for large-scale projects.

Why Cutting PVC Sheets Requires Special Attention

Understanding PVC Sheet Properties

PVC sheets are known for their unique properties, making them a popular choice for various applications. However, these same properties also mean that cutting them requires special attention.

Lightweight and Durable: PVC sheets are easy to handle but can be tough to cut if the wrong tools are used. Their durability means they can resist wear and tear, but improper cutting techniques can lead to cracks or uneven edges.

Thermo-formable: These sheets can be heated and bent into desired shapes, which is great for customization. However, this also means that excessive heat from cutting tools can warp or damage the material if not handled carefully.

Different Thicknesses: PVC sheets come in various thicknesses, such as 1/8”, 5mm, 10mm, and 20mm. Thinner sheets (under 5mm) can be cut with simple tools like utility knives, while thicker sheets require power tools like circular saws or jigsaws. Choosing the wrong tool for the thickness can result in poor cuts or even damage to the material.

Safety Considerations

Cutting PVC sheets involves more than just getting the job done—it’s about doing it safely. The process can pose several risks if proper precautions aren’t taken.

Why Safety is Crucial: PVC sheets can produce sharp edges or splinters when cut, which can cause injuries. Additionally, using power tools without proper care can lead to accidents. Safety should always be a top priority to prevent harm and ensure a smooth workflow.

Potential Hazards:

Sharp Edges and Splinters: Cutting PVC sheets can leave rough edges that may cut or scratch your skin. Always handle cut pieces with care.

Tool-Related Injuries: Power tools like saws and knives can be dangerous if not used correctly. Dull blades or improper handling can lead to slips and injuries.

Safety Gear:

Gloves: Wear cut-resistant gloves to protect your hands from sharp edges and splinters.

Safety Glasses: Protect your eyes from flying debris or dust generated during cutting.

Closed-Toe Shoes: Prevent injuries from dropped tools or heavy materials.

Tools and Materials Needed to Cut PVC Sheets

Essential Tools for Cutting PVC Sheets

Cutting PVC sheets requires the right tools to ensure clean, precise cuts. Whether you're working on a small DIY project or a larger industrial task, having the proper equipment is essential.

Utility Knives, Craft Knives, and Specialty PVC Cutters: These tools are ideal for cutting thin PVC sheets (under 5mm). A sharp utility knife can make clean cuts, while specialty PVC cutters are designed for smoother edges. Craft knives are perfect for intricate shapes and detailed work.

Straight Edges, Rulers, and Masking Tape: Precision is key when cutting PVC sheets. A straight edge or ruler helps guide your cuts, ensuring they are straight and accurate. Masking tape can be applied along the cutting line to prevent splintering and protect the surface of the sheet.

Cutting Mats: To protect your work surface from scratches or damage, use a cutting mat. It also provides a stable base for cutting, reducing the risk of slips or uneven cuts.

H3: Power Tools for Thicker Sheets

For thicker PVC sheets (over 5mm), manual tools may not be sufficient. Power tools offer the strength and precision needed to handle these materials effectively.

Circular Saws, Jigsaws, and Band Saws: These tools are perfect for cutting thicker PVC sheets. A circular saw with a fine-toothed blade is ideal for straight cuts, while a jigsaw allows for curved or intricate designs. Band saws are great for cutting large sheets with precision.

CNC Machines and Laser Cutters: For industrial applications, CNC machines and laser cutters provide unmatched precision and speed. CNC machines are ideal for complex shapes and large-scale projects, while laser cutters offer clean, detailed cuts. However, laser cutting may produce fumes, so proper ventilation is necessary.

Waterjet Cutting: This method uses a high-pressure water stream to cut through thick PVC sheets (up to 1 inch). It’s highly precise and doesn’t generate heat, making it suitable for materials that could warp under high temperatures.

How to Cut PVC Sheets: Step-by-Step Guide

Cutting Thin PVC Sheets (Under 5mm)

Manual Cutting with a Utility Knife

Cutting thin PVC sheets (under 5mm) can be done easily with basic tools. Here’s a step-by-step guide to ensure clean and precise cuts:

Mark the Cutting Line: Use a pen or pencil to draw the cutting line on the PVC sheet. This ensures accuracy and helps guide your cuts.

Apply Masking Tape: Place masking tape along the cutting line to prevent splintering and protect the surface of the sheet.

Use a Straight Edge: Align a straight edge or ruler along the marked line to guide your utility knife. This ensures a straight and clean cut.

Score the Sheet: Gently score the sheet along the cutting line multiple times. Avoid applying too much pressure to prevent cracking.

Snap the Sheet: Once scored, carefully snap the sheet along the line. The PVC should break cleanly, leaving a smooth edge.

Using a Panel Shearing or Plotter Machine

For those who need to cut multiple thin PVC sheets quickly, panel shearing or plotter machines are excellent options.

How They Work: These machines use precise blades or cutting heads to slice through PVC sheets with high accuracy.

Advantages: They offer faster cutting speeds and consistent results, making them ideal for large-scale projects or repetitive tasks.

Cutting Thicker PVC Sheets (Over 5mm)

Using a Circular Saw

Thicker PVC sheets (over 5mm) require more robust tools like circular saws. Here’s how to do it:

Choosing the Right Blade: Use a fine-toothed HSS (High-Speed Steel) blade designed for plastics. This reduces the risk of melting or chipping.

Setting Up the Saw: Ensure the saw’s base plate is flush with the sheet and use a straight edge as a guide for stability.

Avoiding Melting: Cut slowly and steadily to prevent friction, which can cause the PVC to melt. Lubricating the blade with glycerin can also help.

Using a Jigsaw for Curved Cuts

For curved or intricate shapes, a jigsaw is the best tool:

Selecting the Right Blade: Choose a fine-toothed blade specifically designed for cutting plastics. This ensures clean cuts without cracking.

Cutting Curves: Move the jigsaw slowly and steadily through the material. Avoid forcing the blade to prevent deflection or bending.

Starting Holes: For interior cuts, drill pilot holes to allow the jigsaw blade to enter smoothly.

Waterjet Cutting for Precision

Waterjet cutting is ideal for thick PVC sheets (up to 1 inch) and complex designs:

How It Works: A high-pressure water stream cuts through the material with extreme precision, without generating heat.

Advantages: It produces clean, smooth edges and is perfect for intricate shapes or large-scale production.

Professional Services: Due to the high cost of equipment, waterjet cutting is often outsourced to professionals for industrial projects.

Summary Table: Cutting Methods for PVC Sheets

| Method | Best For | Tools Needed | Tips |

| Utility Knife | Thin sheets (under 5mm) | Utility knife, straight edge, masking tape | Score multiple times for a clean break. |

| Panel Shearing Machine | Thin sheets, large-scale projects | Shearing or plotter machine | Ideal for repetitive tasks and high precision. |

| Circular Saw | Thick sheets (over 5mm), straight cuts | Circular saw, fine-toothed HSS blade | Cut slowly to avoid melting. |

| Jigsaw | Thick sheets, curved or intricate designs | Jigsaw, fine-toothed blade | Use pilot holes for interior cuts. |

| Waterjet Cutting | Thick sheets, complex designs | Professional waterjet cutter | Best for industrial applications due to high precision and no heat damage. |

Advanced Cutting Methods for PVC Sheets

When working with PVC sheets, especially for complex designs or large-scale projects, advanced cutting methods can save time and improve precision. These methods are ideal for industrial applications or when high accuracy is required.

CNC Cutting for Complex Designs

What is CNC Cutting?

CNC (Computer Numerical Control) cutting is a highly precise method that uses computer-guided machines to cut materials. For PVC sheets, CNC machines use routers or blades to follow digital designs, ensuring accuracy and consistency.

How CNC Machines Work: The machine reads a digital file and moves the cutting tool along the specified path. This allows for intricate shapes and designs that would be difficult to achieve manually.

Benefits: CNC cutting is perfect for large-scale production or projects requiring complex shapes. It reduces material waste and ensures uniformity across multiple pieces.

Industries That Use CNC Cutting: Signage, advertising, and construction industries often rely on CNC cutting for creating detailed PVC displays, molds, and architectural elements.

Laser Cutting PVC Sheets

How Laser Cutting Works

Laser cutting uses a high-powered laser beam to cut through materials. For PVC sheets, this method offers exceptional precision and speed.

Precision and Speed: Laser cutters can create intricate designs with clean edges, making them ideal for detailed work. They are also faster than manual methods for complex patterns.

Potential Drawbacks: Laser cutting PVC can produce odors, coking (burn marks), and toxic gases like chlorine. Proper ventilation and air purification systems are essential.

Safety Precautions: Always wear protective gear, ensure good ventilation, and use laser cutters in controlled environments to minimize health risks.

Abrasive Wheel Cutting for Rough Cuts

When to Use an Abrasive Cutter

Abrasive wheel cutting is a straightforward method suitable for rough cuts or single-piece processing. It’s not ideal for fine details but works well for quick, basic cuts.

Suitable for Rough Cuts: This method is best for projects where precision is not critical, such as cutting large sheets into smaller pieces.

Limitations: Abrasive cutting generates a lot of debris and leaves rough edges. It’s not suitable for projects requiring smooth, polished finishes.

Comparison with Other Methods: Unlike CNC or laser cutting, abrasive wheel cutting is less precise but more affordable and easier to set up for small-scale tasks.

Summary Table: Advanced Cutting Methods for PVC Sheets

| Method | Best For | Advantages | Limitations |

| CNC Cutting | Complex designs, large-scale production | High precision, reduces material waste | Expensive equipment, requires expertise |

| Laser Cutting | Intricate designs, high-speed cutting | Clean edges, fast for detailed work | Produces odors and toxic gases |

| Abrasive Wheel Cutting | Rough cuts, single-piece processing | Affordable, easy to use | Rough edges, generates debris |

Finishing and Smoothing Cut Edges

After cutting PVC sheets, the edges are often rough and uneven. Finishing these edges is a crucial step to ensure safety, improve aesthetics, and prepare the material for further use. Here’s why finishing matters and how to achieve smooth, polished edges.

Why Finishing is Important

Hazard Prevention: Rough edges can be sharp and dangerous, posing a risk of cuts or injuries during handling. Smoothing them reduces this risk.

Professional Appearance: Rough edges look unprofessional, especially in visible applications like signage or displays. Finishing gives the material a clean, polished look.

Better Fit for Joining: Smooth edges ensure that pieces fit together seamlessly when bonding or assembling, improving the overall quality of the project.

Methods for Finishing Edges

Sanding

Sanding is the most common method for smoothing PVC edges. It’s simple, effective, and works well for both thin and thick sheets.

How to Sand: Start with coarse-grit sandpaper (around 100 grit) to remove large imperfections. Gradually move to finer grits (up to 600+) for a smooth, polished finish.

Tips: Sand in a consistent direction to avoid scratches. For large projects, use a power sander to save time, but avoid excessive heat buildup.

Routing

Routing is ideal for thicker PVC sheets or when a perfectly flush edge is needed.

How to Route: Use a trim router with a flush-cutting bit. Guide the router along the edge to remove any uneven material.

Tips: Ensure the router is set to the correct depth and speed. Practice on a scrap piece before working on the final project.

Deburring Tools

Deburring tools are quick and efficient for removing small slivers or burs from the edges.

How to Use: Simply run the deburring tool along the edge in a single swipe. The angled blade quickly removes any protruding material.

Tips: This method is best for quick touch-ups or when working on smaller pieces.

Edge Finishing Methods

| Method | Best For | Tools Needed | Tips |

| Sanding | Smoothing rough edges on all thicknesses | Sandpaper (100 to 600+ grit), power sander | Start with coarse grit and move to finer grits for a polished finish. |

| Routing | Thick sheets, flush edges | Trim router, flush-cutting bit | Practice on scrap material before working on the final piece. |

| Deburring | Quick removal of slivers and burs | Deburring tool | Use for small touch-ups or finishing edges on smaller pieces. |

Painting and Bonding PVC Sheets

Once you’ve cut and finished your PVC sheets, the next steps often involve painting or bonding them for your project. Whether you’re creating signage, displays, or custom designs, proper painting and bonding techniques ensure a professional and durable result.

How to Paint PVC Sheets

Painting PVC sheets is a straightforward process, but it requires the right materials and preparation to ensure the paint adheres well and lasts.

Recommended Paints:

Vinyl Paint: Specifically designed for PVC, it offers excellent adhesion and durability.

Acrylic Paint: A versatile option that works well on PVC and is available in a wide range of colors.

Polyurethane Paint: Provides a tough, long-lasting finish, ideal for outdoor or high-wear applications.

Preparing the Surface:

Clean the PVC sheet with isopropyl alcohol to remove dust, grease, or any contaminants. This step ensures the paint adheres properly.

Allow the surface to dry completely before applying paint.

Do You Need a Primer?:

Bonding PVC Sheets

Bonding PVC sheets is essential for creating strong, durable connections, whether you’re joining PVC to itself or other materials.

Painting and Bonding PVC Sheets

| Task | Materials/Tools | Steps/Tips |

| Painting PVC Sheets | Vinyl, acrylic, or polyurethane paint | Clean with isopropyl alcohol, apply paint evenly, and consider using a primer. |

| Bonding PVC to Itself | PVC cement | Apply cement to both surfaces, press together, and hold until the bond sets. |

| Bonding PVC to Other Materials | Epoxy or polyurethane adhesive | Clean surfaces, apply adhesive evenly, and use clamps for large pieces. |

Conclusion

Cutting PVC sheets needs the right tools and techniques. Safety is crucial when using cutting tools. Different methods suit various thicknesses and applications.

Always measure twice and cut once. Use the right cutting method for your project. Finish edges for a professional look and safe handling.

Frequently Asked Questions (FAQs)

Can I Cut PVC Sheets with a Regular Knife?

What is the Best Way to Cut Thick PVC Sheets?

Can I Use a Laser Cutter for PVC Sheets?

How Do I Smooth the Edges After Cutting?

Can PVC Sheets Be Painted?